Difference between revisions of "Clean"

(Added photo of kapton rig, taken before it was disassembled) |

|||

| Line 7: | Line 7: | ||

Materials studied have included Kapton, Butyl, EVOH, and Nylon. | Materials studied have included Kapton, Butyl, EVOH, and Nylon. | ||

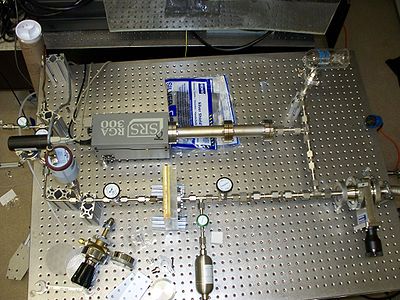

| − | [[File:Kapton03.jpg|400px|thumb|left| | + | [[File:Kapton03.jpg|400px|thumb|left|Permeability measurement apparatus]] |

Revision as of 11:37, 25 July 2009

Rn permeability is an important factor in the design of low radioactive background experiments such as CLEAN. In these types of experiments, the presence of Rn within the detector will create false positives indistinguishable from real signal. To protect against this problem, radon seals must be made.

In this experiment, several different materials are tested for their ability to screen Rn. The apparatus used consists of a high- and low-pressure chamber separated by a film holder, which holds a film (of the material to be studied) in a leak tight configuration. Test gas is inserted into the high-pressure chamber (up to 10^3 torr), which creates a pressure difference across the film, causing permeation to the low-pressure chamber (10^-6 torr) to occur.

We are interested in the material's permeability and in the breakthrough time (the time needed for test gas to permeate through the material). By observing pressure changes in the low-pressure chamber with a Residual Gas Analyzer, we measure these values for different materials with respect to He, Ne, Ar, Kr, and Xe. We are then able to extrapolate from this data to estimate Rn values.

Materials studied have included Kapton, Butyl, EVOH, and Nylon.